Ultimate Guide to Laser Levels

Walk onto any jobsite and you’ll see it. A contractor is pulling out a laser level. Why? Because when it comes to precision, nothing beats it.

Forget the old bubble level (though we still sell them!). Today’s projects demand accuracy, speed, and reliability. Whether you’re framing walls, grading a jobsite, laying tile in a kitchen, or trying to win an argument with your spouse on who hung that picture more accurately, a laser level gets the job done right—the first time.

At Contractor Cave, we are laser-focused on providing the best tools for tradespeople, from simple hammers to sophisticated laser levels. This guide is your all-in-one resource. We’ll break down the different types of professional-grade laser levels, key features to look for, how to pick the right one for your industry, and best practices for using and maintaining it. Think of this as your playbook for laser accuracy.

Ready to level up your measuring game? Let’s shine a beam on some knowledge!

No Time to Read? Here’s a TL;DR:

- Laser levels project precise lines or dots, significantly improving accuracy and speed for tasks like framing, tiling, and grading.

- Different types of laser levels (line, cross-line, rotary, dot, grade, pipe) are suited for specific applications, from indoor installations to large-scale outdoor construction.

- Key features to consider when choosing a laser level include accuracy, beam color, range, IP ratings, self-leveling capabilities, and power source.

- Proper setup, regular calibration checks, and careful maintenance are crucial for ensuring the long-term accuracy and performance of a laser level.

Why Use a Laser Level?

The bubble level (also known as a spirit level) has been a carpenter’s friend for centuries. It’s simple, cheap, and reliable. That little bubble has been keeping structures standing, woodworking straight, and machines level since the days of the ancient Egyptians. However, because the level is an engineer’s tool, and engineers love to improve things, it was only a matter of time before someone figured out a way to create a better level. Enter the laser level.

First introduced in 1985 by Spectra-Physics Scanning Systems, Inc., laser levels bring something new to the table. They don’t just help you find level — they project it across a space, giving you a clear, visible line or dot you can build from.

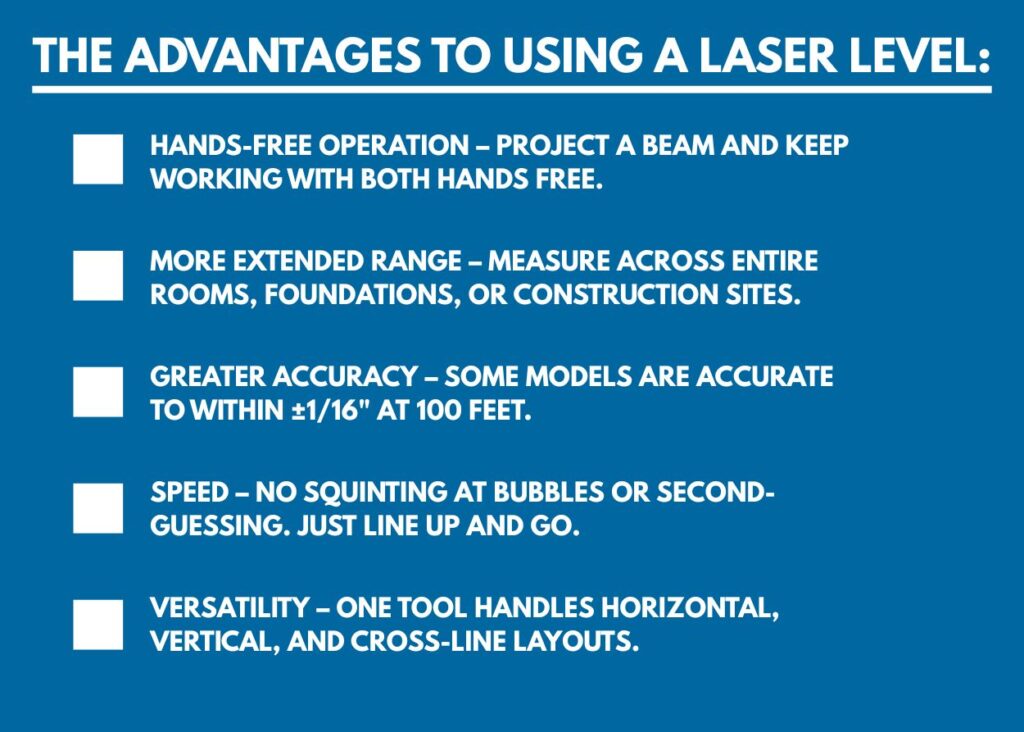

The advantages:

- Hands-free operation – project a beam and keep working with both hands free.

- More extended range – measure across entire rooms, foundations, or construction sites.

- Greater accuracy – some models are accurate to within ±1/16″ at 100 feet.

- Speed – no squinting at bubbles or second-guessing. Just line up and go.

- Versatility – one tool handles horizontal, vertical, and cross-line layouts.

Here’s the bottom line: laser levels don’t just replace bubble levels. They expand what you can do. If you need simple leveling jobs over short distances, a traditional bubble level will suffice. Over long distances, such as construction sites, the precision, speed, and convenience of using a laser level will save time and money, both in labor costs and by reducing the risk of costly measuring mistakes.

Types of Laser Levels and When to Use Them

There’s no one-size-fits-all when it comes to laser levels. Each type has strengths and weaknesses. Pick the wrong one, and you’ll be fighting your tool instead of using it. Before you start picking a laser, ask yourself three questions:

- What’s the job or application that you’re doing?

- What is the environment that you’re working in?

- What special needs might there be?

Once you’ve got your answers on hand, pick one of the lasers below:

1. Line Lasers

Line lasers project straight horizontal or vertical lines onto surfaces, making them perfect for short-range, indoor projects.

Best for:

- Framing walls and partitions

- Installing cabinets

- Hanging shelves or pictures

- Aligning tile

2. Cross-Line Lasers

Shoot both vertical and horizontal lines that intersect at a 90° angle. They’re best used for indoor applications.

Best for:

- Setting tile layouts

- Electrical outlet alignment

- Stud wall construction

- Drop ceiling installations

3. Rotary Lasers

These spin 360°, projecting a continuous line around an entire room or jobsite. While rotary lasers sound like something out of Star Wars, they’re actually used for precise leveling and alignment for various construction and surveying tasks.

Best for:

- Outdoor construction

- Grading and site prep

- Foundation layouts

- Landscape design

- Large commercial jobs

4. Dot Lasers (Point Lasers)

Dot lasers project points instead of lines. They are excellent for transferring layouts—in fact, with a dot laser, one person can quickly and precisely do the demanding task of marking layouts.

Best for:

- Transferring points from the floor to the ceiling

- Aligning plumbing pipes

- Marking stud positions

- Door and window installations

5. Grade Lasers

A cousin of the rotary laser, grade lasers are specialized rotary lasers that set slopes — single grade or dual grade. Technically, a rotary laser could be used to grade with a bit of improvisation and experience, but grade lasers do.

Best for:

- Road construction

- Drainage work

- Landscaping and excavation

- Sports fields and golf courses

6. Pipe Lasers

As the name suggests, these are made for underground utility work. Because crests and valleys in a pipe system can block or slow down the liquid flowing inside, pipes must maintain a consistent grade throughout the system. To keep that grade, a pipe laser shoots a beam down a pipe trench for alignment.

Best for:

- Sewer installation

- Drainage pipe runs

- Stormwater systems

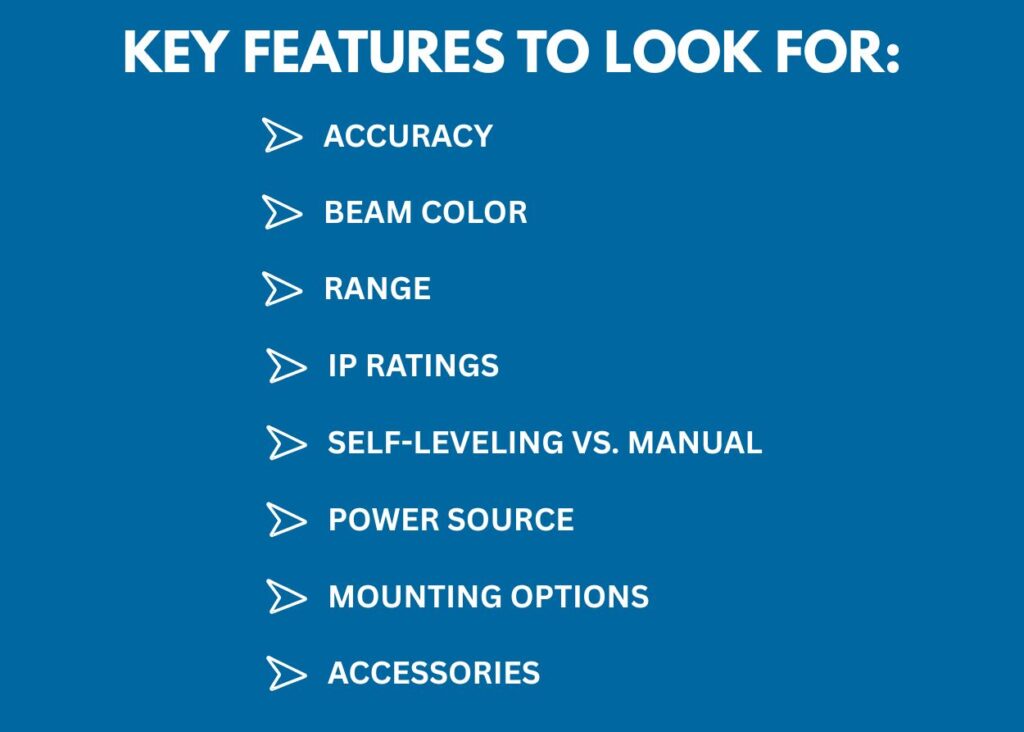

Key Features to Look For

Buying a laser level isn’t just about grabbing the first one on the shelf. The specs matter. Here are the features you should weigh:

- Accuracy – Look for tolerance ratings. A good professional model is accurate to ±1/16″ at 30 feet. For big jobs, that precision adds up.

- Beam Color – It’s not about whether you like green or red. Green lasers are four times brighter and more visible in daylight. Red lasers use less battery power and are typically less expensive.

- Range – Rotary lasers with a detector can reach up to 1,000 feet. Line lasers are typically best suited for shorter ranges, generally around 100 feet.

- IP Ratings – This indicates the level of protection against dust and water your tool provides, with higher numbers indicating more protection. For example, a level rated IP54 is dust- and splash-resistant, while a level rated IP67 is dust-tight and waterproof up to 1 meter.

- Self-Leveling vs. Manual – Self-leveling saves time and improves accuracy. Manual is fine for occasional DIY work.

- Power Source – Rechargeable lithium-ion batteries offer longer life. Alkaline batteries are easier to replace on the go. Some models allow you to switch between both.

- Mounting Options – Magnetic mounts, tripods, ceiling clamps, and wall brackets make a big difference on the job.

Accessories – Don’t overlook detectors, measuring rods, target plates, and remote controls. These make your laser more versatile.

How to Choose the Right Laser Level for Your Work

Different trades need different tools. Here’s a trade-by-trade guide:

- General Contractors – A rotary laser with a detector is your best friend. It handles site layout, grading, and foundation work.

- Electricians – A cross-line laser helps with conduit runs, switch and outlet alignment, and panel installs.

- Plumbers – A dot laser is excellent for aligning pipe runs. A cross-line laser is perfect for bathroom installs.

- Tile Installers – A line laser makes laying floors and backsplashes easier and straighter.

- Surveyors & Landscapers – Grade lasers give you precise slope control outdoors.

- DIY Homeowners – A basic line or cross-line laser is plenty for hanging shelves, picture frames, or building a deck.

Think of it this way: line lasers handle inside precision. Rotary and grade lasers handle outside distances.

Step-by-Step: Setting Up and Calibrating a Laser Level

Laser levels aren’t difficult to use, but a little setup goes a long way.

- Set up your tripod or mount. Always start on stable ground.

- Turn on and self-level. If manual, use the built-in bubble vials.

- Select your mode: Horizontal, vertical, cross-line, or rotary spin.

- Mark your reference points. Use pencil, chalk, or marker.

- Check calibration. A quick test: project a line, mark it, then rotate the unit 180°. If the new line matches, you’re good to go.

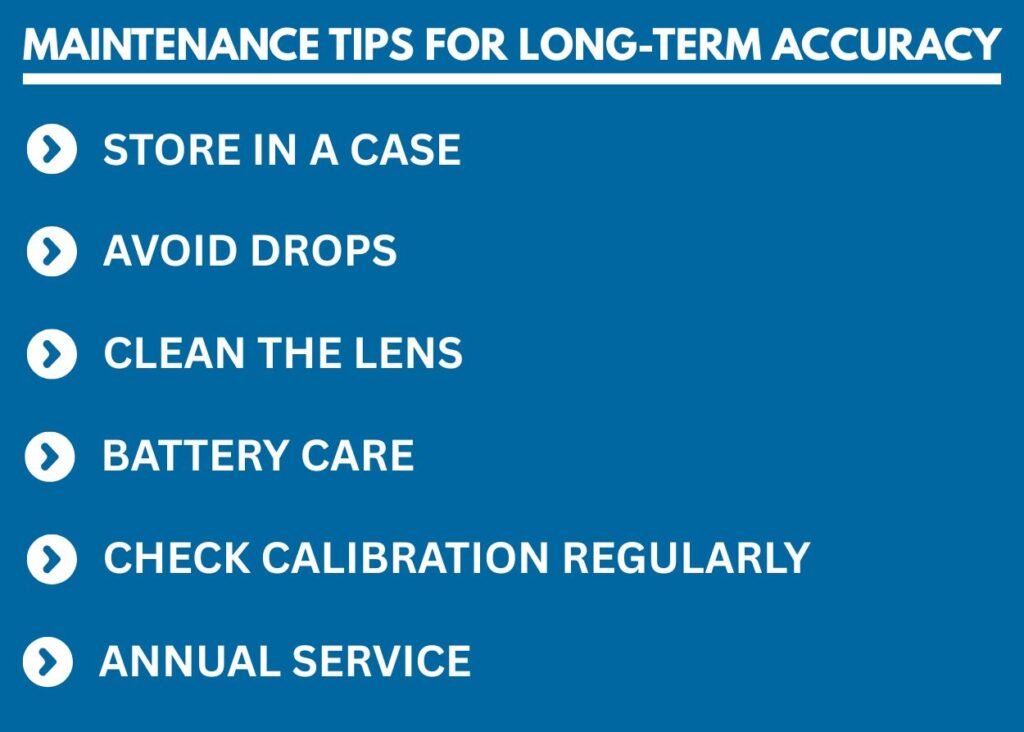

Maintenance Tips for Long-Term Accuracy

Laser levels are built tough, but they’re not indestructible. Treat them like the precision instruments they are.

- Store in a case. The case that came with your laser was specifically designed to protect your laser from dust, dirt, and bumps.

- Avoid drops. Lasers are extremely sensitive devices. A slight knock can throw it out of calibration.

- Clean the lens. Use a microfiber cloth. No harsh cleaners.

- Battery care. Recharge lithium batteries before they’re completely drained.

- Check calibration regularly. Especially after transport or hard use.

- Annual service. Many manufacturers recommend yearly calibration checks by an authorized service center.

Real-World Examples

Let’s make this practical.

- A framing crew uses a rotary laser to lay out the foundation, walls, and roofline. They save hours compared to string lines and bubble levels.

- An electrician hangs multiple light fixtures in a gym using a cross-line laser. Every fixture lines up perfectly without rechecking measurements.

- A landscaper installs a drainage system with a grade laser. They achieve the right slope on the first try, avoiding costly rework.

- A homeowner builds a deck with a basic line laser. The joists and railing posts come out straight, and the finished deck has a professional appearance.

That’s the difference between guessing and knowing.

Common Mistakes to Avoid

Even with the best tools, mistakes can still occur. Here’s what to watch out for:

- Skipping calibration checks: Always check for calibration when in use. Uncalibrated lasers lead to compounding errors.

- Using the wrong laser type: These lasers are designed for specific purposes. Using the wrong or inadequate tool for the wrong job will only lead to frustration.

- Not securing the tripod: Even a slight shift ruins accuracy.

- Overlooking IP ratings: Don’t bring a low-rated unit into rain or dust-heavy sites. You won’t get good data, and you’ll probably damage the unit.

- Forgetting detectors outdoors: You won’t see the line in bright sunlight without one.

Wrapping It Up

Laser levels aren’t just gadgets. They’re job-site essentials that save time, prevent mistakes, and deliver professional results.

Whether you’re a seasoned contractor, a surveyor, or a weekend DIYer, the right laser level helps you build faster, straighter, and smarter.

At Contractor Cave, we believe in one thing: the right tool for the right job. That’s why we carry laser levels for every trade and budget. Because working smart isn’t just about skill — it’s about using the right gear to back it up.

Contact us or visit us today to explore your next laser level! We’re plumb full of knowledge and experience to help you pick the one that fits your work, your budget, and your goals. From classic hand tools to the latest power tools, you can find them at our store in Woodstock, ON, or shipped to you from our online store, to your doorstep virtually anywhere in Canada!